Safer sealing solutions for the Refining industry.

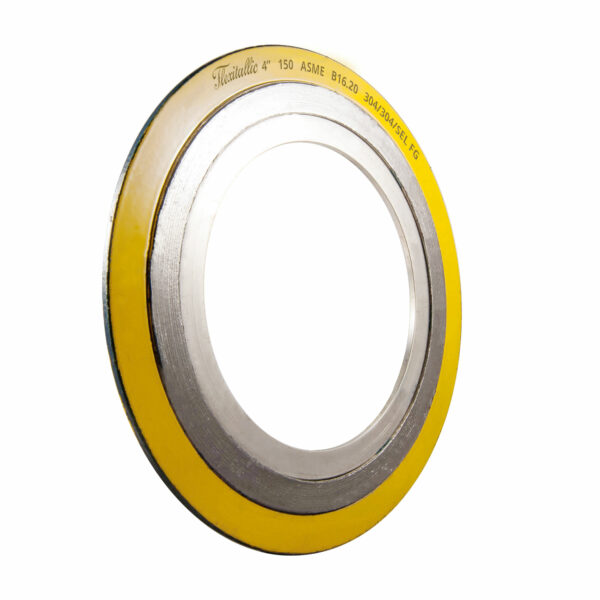

Refineries are large complex structures, requiring different gaskets at different stages of the refining process. These can range from sheet materials to Thermiculite® spiral wound gaskets for high temperature and pressure applications, or blind gaskets for sealing during shutdown. Using our knowledge and experience we’ll make sure you have the right sealing material for each joint.

It’s our thorough understanding of the challenges today’s refineries pose that enables us to minimise the risk of gasket failure. Whether quoting for a new plant, refurbishment or replacement parts, we take a holistic view of the demands on each joint to provide you with the most appropriate gasket for your needs.

Featured products for Refining

Download our Refining brochure

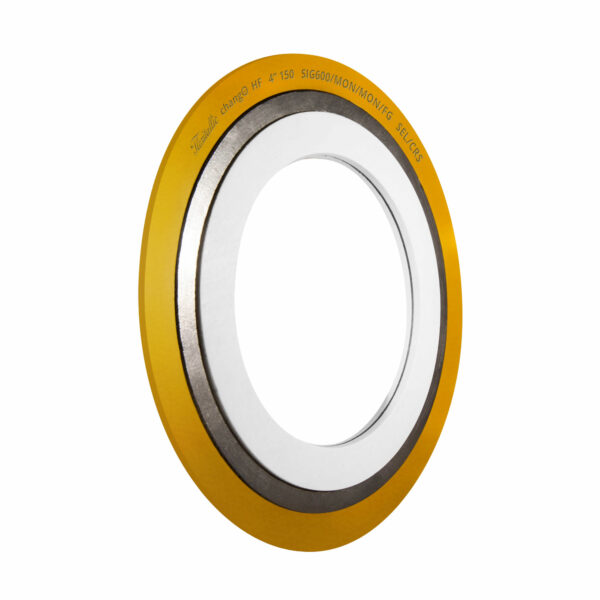

The newest members of Flexitallic products, Change, and Change-HF gaskets have been used to solve the most challenging applications in refineries all around the world. Change type gaskets have replaced many problematic heat exchangers where the highly cyclic nature of the process have created sealing problems with the traditional gaskets such as Kammprofile, or metal jacketed gaskets. Change-HF gaskets are now considered the best choice in sealing the very corrosive and toxic nature of HF acid, used in Alky units in refineries.

- Benoit Labre, Operations Director, Flexitallic UK Ltd